The Evolution of Grid Electricity Storage

Management of Wind and Solar Power

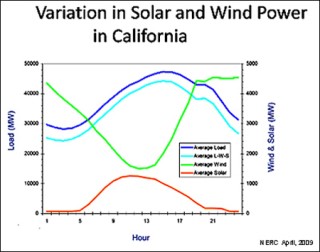

Wind and solar power, for international,

climate, and environmental reasons, are becoming more and more popular.

However, electricity generated by the wind and sun is highly variable, both on

an hourly basis and seasonally. This is especially true for wind in the spring

(April) and fall (October) when wind conditions can change very quickly. During

winter the wind is rather strong and steady. During summer wind is weak and

unchanging. When the wind suddenly begins to blow, a power surge is encountered

on the grid. Likewise, when wind suddenly dies, there is a large power drop. If

the wind suddenly dies, the load has to be taken up by traditional coal and gas

plants. Because these traditional plants take considerable time to power up,

they must be run in "spinning standby", i.e. running as backup but

not producing any electricity. Likewise, sun power is on a "diurnal"

cycle, that is, it repeats itself every 24 hours and only shines from 9 to 15

hours a day depending on season and location. The first chart above from an

April day in California illustrates the issues.

Wind and solar power, for international,

climate, and environmental reasons, are becoming more and more popular.

However, electricity generated by the wind and sun is highly variable, both on

an hourly basis and seasonally. This is especially true for wind in the spring

(April) and fall (October) when wind conditions can change very quickly. During

winter the wind is rather strong and steady. During summer wind is weak and

unchanging. When the wind suddenly begins to blow, a power surge is encountered

on the grid. Likewise, when wind suddenly dies, there is a large power drop. If

the wind suddenly dies, the load has to be taken up by traditional coal and gas

plants. Because these traditional plants take considerable time to power up,

they must be run in "spinning standby", i.e. running as backup but

not producing any electricity. Likewise, sun power is on a "diurnal"

cycle, that is, it repeats itself every 24 hours and only shines from 9 to 15

hours a day depending on season and location. The first chart above from an

April day in California illustrates the issues.

The dark blue line is the electrical load

peaking in early afternoon. The green line is the contribution from wind power

weakest about noon. The orange line is the contribution from a solar plant,

peaking in the afternoon but not enough to satisfy the demand. The light blue

line is the load minus wind and solar illustrating that renewables can only be

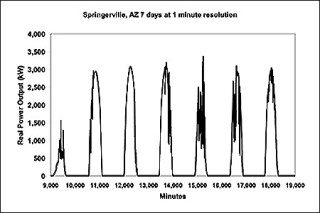

a part of the overall mix. The one week of solar power chart at the right from

Arizona illustrates very well the natural, but fairly predictable, variability

of solar energy. The power on the first, fifth, and sixth days indicate that

there was some cloud cover on those days.

The dark blue line is the electrical load

peaking in early afternoon. The green line is the contribution from wind power

weakest about noon. The orange line is the contribution from a solar plant,

peaking in the afternoon but not enough to satisfy the demand. The light blue

line is the load minus wind and solar illustrating that renewables can only be

a part of the overall mix. The one week of solar power chart at the right from

Arizona illustrates very well the natural, but fairly predictable, variability

of solar energy. The power on the first, fifth, and sixth days indicate that

there was some cloud cover on those days.

This variability in renewable energy sources creates issues in the management of grid electricity generation. When renewables are only 2% of the supply as currently the case, variability is not a big problem. 2% can be easily covered by existing standby capacity established for grid emergencies. Standby capacity is normally about 5%, but can be as high as 10% during a summer heat wave. As more and more energy is derived from renewable sources and approaches 20% or more of the total, the grid must be intelligent and be able to store energy from the wind and sun for future requirements. Having some type of grid storage is key for the future of renewable energy sources.

"Electricity" cannot be stored on the grid; generation must be approximately equal to consumption at all times. However, "energy" can be stored although losses are incurred in the process. At the moment, there are three proven methods of storing electric energy on the scale of the grid - batteries, molten salt and compressed air. There are also a few new technologies on the horizon. Let us take a look at proven as well as some new technologies.

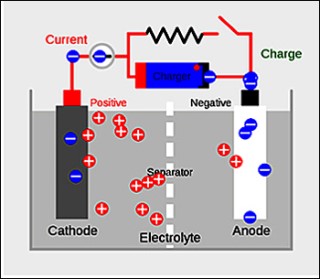

Batteries - Rechargeable Basics

Batteries have chemicals inside and produce

electricity by converting the chemical energy into electrical energy. A

rechargeable battery is different from a disposable battery in that its

chemicals can be refreshed, whereas in a throw away battery when the chemicals

are used up, the battery is dead. The positive and negative electrodes are

known as the cathode and anode respectively. During the recharge process,

electrons from a charger of the same polarity but with a higher voltage, are

injected into the anode creating a reverse current from normal battery

operation. Positive ions (usually lithium) normally located at the anode, are

driven from the anode through the separator, to the cathode building up a net

positive charge.

Batteries have chemicals inside and produce

electricity by converting the chemical energy into electrical energy. A

rechargeable battery is different from a disposable battery in that its

chemicals can be refreshed, whereas in a throw away battery when the chemicals

are used up, the battery is dead. The positive and negative electrodes are

known as the cathode and anode respectively. During the recharge process,

electrons from a charger of the same polarity but with a higher voltage, are

injected into the anode creating a reverse current from normal battery

operation. Positive ions (usually lithium) normally located at the anode, are

driven from the anode through the separator, to the cathode building up a net

positive charge.

During normal battery use, electrons are attracted to the cathode and flow the opposite way - from the anode. through the load to the cathode. Both the anode and cathode are materials into which and from which, lithium ions can migrate. A liquid electrolyte, usually a lithium salt, acts as a positive ion carrier between the cathode and the anode.

Useful work can only be extracted when electrons flow through a "closed" external circuit. Rechargeable batteries have a higher initial cost, but can be recharged very cheaply and used many times. They therefore have a lower total lifetime cost. Rechargeable batteries vary in size from AAA camera sized batteries to huge utility scale systems.

Grid Scale Battery Storage

As mentioned above, electricity generated

by wind and sun is highly variable, both on an hourly basis and seasonally.

Electrical energy can be stored in batteries during times when production from

wind (or sun) exceeds consumption and the energy can be recovered when

consumption exceeds production. In this way, electricity production does not

need to be drastically scaled up and down to meet momentary drops or to meet

peak demand. Instead, production can be maintained at a more constant level.

This sounds easier than it really is.

As mentioned above, electricity generated

by wind and sun is highly variable, both on an hourly basis and seasonally.

Electrical energy can be stored in batteries during times when production from

wind (or sun) exceeds consumption and the energy can be recovered when

consumption exceeds production. In this way, electricity production does not

need to be drastically scaled up and down to meet momentary drops or to meet

peak demand. Instead, production can be maintained at a more constant level.

This sounds easier than it really is.

Here are some battery issues that have to be considered by utilities managing wind sites. How much battery capacity versus wind capacity do you need to make a significant difference in variability? The answer depends on the conditions at an individual site but is believed to range between 10% and 20% of the wind system capacity. What time of day do you begin to let the battery discharge after being charged over night? Most analysts would say "during the peak usage" which changes from season to season but is fairly well known. What do you do when the battery does not have a full charge from the night before? Analysts can develop algorithms to shorten the discharge period depending on the amount of charge in the battery, but still surround the peak time period. What do you do when the wind is very strong and the electricity generated by the wind exceeds the carrying capacity of the grid? This answer is rather straight forward (but not likeable). When the battery is full and the grid can accept only a limited amount of electricity, the excess needs to be dumped into the ground by the battery management system.

As can be seen from the examples above, management of the grid with renewable generation takes on some new dimensions. The answers to the various issues are not all known at this time. Hence, efforts are underway both from a simulation point of view and from "test" live projects to understand the issues and to develop solutions to better manage renewable generation. Several associations and leading-edge utilities currently have test projects underway.

Molten Salt Storage

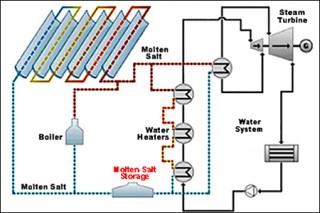

All molten salt storage projects are

currently part of trough CSP systems where the salt transfer fluid is heated to

about 550°C (990°F) in tubes at the focus point of long parabolic mirror sun

collectors. The very hot liquid flowing salt then heats a water system where

steam propels a standard turbine generator. The molten salt is a mixture of 60

percent sodium nitrate and 40 percent potassium nitrate, commonly called

saltpeter. The molten salt can achieve a higher temperature and hold heat

longer than the oil previously used called therminol. However, the molten salt

must be kept at a temperature of 290°C or more to keep it fluid as the salt

freezes (becomes lumpy with solids) below 220°C. This means that special care

must be taken to ensure that the salt does not freeze in the field piping

during the night. The huge advantage of molten salt is that it can retain its

heat for up to six hours when stored in specially designed storage tanks. This

means that power is still available for up to six hours after the sun goes low

on the horizon - enough to cover the period of peak electrical demand. Because

the trough power approach uses conventional steam turbines, it is easy for the

system to integrate seamlessly into the electrical grid. And because of its

storage ability, the molten salt system can easily compensate for moving cloud

cover and other weather phenomenon.

All molten salt storage projects are

currently part of trough CSP systems where the salt transfer fluid is heated to

about 550°C (990°F) in tubes at the focus point of long parabolic mirror sun

collectors. The very hot liquid flowing salt then heats a water system where

steam propels a standard turbine generator. The molten salt is a mixture of 60

percent sodium nitrate and 40 percent potassium nitrate, commonly called

saltpeter. The molten salt can achieve a higher temperature and hold heat

longer than the oil previously used called therminol. However, the molten salt

must be kept at a temperature of 290°C or more to keep it fluid as the salt

freezes (becomes lumpy with solids) below 220°C. This means that special care

must be taken to ensure that the salt does not freeze in the field piping

during the night. The huge advantage of molten salt is that it can retain its

heat for up to six hours when stored in specially designed storage tanks. This

means that power is still available for up to six hours after the sun goes low

on the horizon - enough to cover the period of peak electrical demand. Because

the trough power approach uses conventional steam turbines, it is easy for the

system to integrate seamlessly into the electrical grid. And because of its

storage ability, the molten salt system can easily compensate for moving cloud

cover and other weather phenomenon.

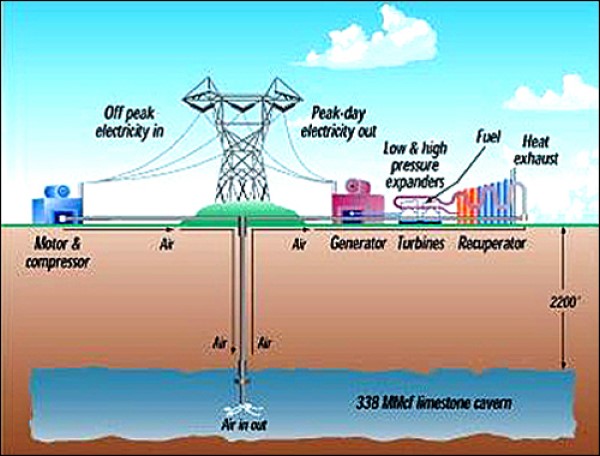

Compressed Air Storage

Compressed Air Energy Storage (CAES) plants

are designed to store electric power off peak when it is not in high demand and

prices are low. Then later, to return the compressed air back to electricity

when demand and prices are high. The source of the original power can be any

form of energy - wind, solar, gas or coal. The first plant of this kind was

built for Alabama Electric Cooperative in 1981. It has been in production ever

since and has met all of its goals. So why hasn't this storage concept caught

on? In one word - cost. Natural gas and coal were very cheap in the following

years and it did not make economic sense to store cheap electricity.

Wind and solar cycles are quite unpredictable and utility scale storage is very appealing to supplement these technologies. Spare electricity in off peak periods is used to compress air to about 750 psi and store it underground in sealed abandoned salt mines and other rock formations. When electricity is in high demand (weekday late afternoons) the air is retrieved, heated up, fed to a turbine/generator, and the electricity is transported back to the grid. The cost to store a kilowatt of electricity is about $1,000. Wind is most powerful at night but needed most during the day, so wind power is ideal for this technology. Solar is best during the peak times, but excess solar power could be generated during one afternoon in the southwest, stored overnight, and then transferred to the east coast for the next day's peak along super transmission highways similar to interstate freeways. Wind and solar power stations are like roads and bridges - once the original costs are paid for, the follow-on maintenance costs are almost free as there are no fuel costs.

According to the Electric Power Research Institute's (EPRI's) energy storage expert, Rich Lordan, "CAES is going to be important." Pacific Gas & Electric is looking forward to participating in a huge 300-megawatt CAES project in Kern County, California. PG&E; needs the storage facility to manage the 4,500 megawatts of new wind power coming online in California in 2012 from the Tehachapi Pass Wind Project. The U.S. DOE and PG&E; are working out the details on the Kern County project. This project is working its way through the California legislature. It will be the largest CAES project in the world and is expected to create new interest in CAES worldwide.

Recent Storage Developments

Flywheel Energy Storage

![]() Due to normal variations in demand, there

are small transient load fluctuations on the grid. When the load is equal to

the power generated, the AC frequency is exactly 60 cycles per second (60

hertz). When the load exceeds the power generation, the frequency drops below

60 cycles. When the load drops below the power generation, the frequency

exceeds 60 cycles. Operators monitoring the grid will either increase or decrease

standby power generators to compensate for these transient fluctuations. This

is called "frequency regulation".

Due to normal variations in demand, there

are small transient load fluctuations on the grid. When the load is equal to

the power generated, the AC frequency is exactly 60 cycles per second (60

hertz). When the load exceeds the power generation, the frequency drops below

60 cycles. When the load drops below the power generation, the frequency

exceeds 60 cycles. Operators monitoring the grid will either increase or decrease

standby power generators to compensate for these transient fluctuations. This

is called "frequency regulation".

One to three percent of the grid capacity is in "spinning standby" mode for frequency regulation. However, these generators are relatively slow in their response to the fluctuations. Gas fired generators that are used for frequency regulation suffer a significant loss in efficiency and incur costs for fuel. They also emit much higher levels of greenhouse gases when cycling up and down.

Flywheel based storage can be a significant help for managing transient fluctuations which will only increase as renewable sources are added to the grid. A flywheel is a mechanical device that converts electrical energy into rotational kinetic energy. It consists of a large very strong carbon composite fibre cylinder that spins inside a vacuum-sealed housing.

A vacuum is used to reduce air friction. Magnetic levitational bearings (no touching parts) are also used to reduce bearing friction. The cylinder rotates at 20,000 or more revolutions per minute (rpm). The amount of energy a flywheel can store is proportional to the weight of the flywheel, but also the square of the rotational speed. Engineers have found the it is better to lighten the flywheel and spin it faster. Doubling the weight doubles the stored energy, but doubling the speed quadruples the amount of energy that can be stored.

Flywheels recycle electricity from the grid by absorbing it when the supply is greater than demand, and injecting it back when needed to meet demand, thus stabilizing the frequency of the grid. This is currently done manually. Flywheels are not intended for long term storage, maximum storage time is about 15 minutes. However, most fluctuations are of short duration. Frequency regulation requires mega-watts of power instantaneously, but only for a few minutes. 98% of the fluctuations can be handled within 15 minutes. The other 2% are generally due to generator issues.

The only sound heard when standing inside the flywheel system is that of the fans used to cool the electronic equipment inside. The round-trip efficiency of a flywheel system is about 85%; the other 15% is used to keep the flywheels turning. The advantages of flywheel-based storage are a very fast response, they help manage renewable fluctuations, no CO2 emissions, lower operating costs than generators and batteries, and they free up one to three percent generating capacity. The main disadvantage of a flywheel system is its short storage time limitation of about 15 minutes. Also, in rare circumstances, a flywheel can be over-driven by high current. If this occurs the composite carbon cylinder can explode into many, many small pieces of very short lived flying hot ash. This is why they have to be enclosed in a heavy metal container. In the "old" days when the cylinders were made of metal, they were sometimes buried in the ground.

Beacon Power, based in Tyngsboro, Mass., was the only grid level flywheel company with a production site. (Although Power Thru Technology, a division of Phillips Service Industries (PSI) in Livonia, MI, has a some very competitive grid test projects installed and plans to ramp up manufacturing.) In 2011 Beacon Power began commercial operations in Stephentown, New York and has connected 20 mega-watts of flywheel energy storage to the grid. At capacity, the Stephentown plant provides approximately 10% of New York State’s typical daily demand for frequency regulation services. The plant consists of a network of 200 flywheels of 100 kilo-watts each. It is monitored and controlled over the internet by independent system operators (ISOs). Beacon Power received a $43 million loan guarantee from the Department of Energy for the project. The loan covered 62.5 percent of the estimated $69 million needed to construct the plant. The New York Energy Research and Development Authority also provided $2 million in funding.

During October, 2011 Beacon Power had to file for Chapter 11 Bankruptcy. In February, 2012, most of the assets of Beacon Power were acquired by Rockland Capital, a multi-hundred-million-dollar private equity firm focused on energy related investments, in an asset only purchase. The majority of former employees were rehired in addition to the purchase of the 20-megawatt Stephentown facility. Rockland agreed to keep Beacon Power going. AS of October, 2018, Beacon Power operates three flywheel energy storage plants that provide frequency regulation service to three different US markets with more than 400 flywheels in commercial operation.

Liquid Metal Batteries – MIT

Researchers, Professor Donald Sadoway and

Dr. David Bradwell, at MIT are working on a revolutionary all liquid metallic

battery. The metals are literally in a liquid state because the battery

operates at a whopping temperature of 700°C (about 1300°F).

Researchers, Professor Donald Sadoway and

Dr. David Bradwell, at MIT are working on a revolutionary all liquid metallic

battery. The metals are literally in a liquid state because the battery

operates at a whopping temperature of 700°C (about 1300°F).

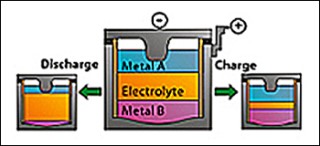

As with all batteries, there are two electrodes separated by an electrolyte. As shown in the schematic on the right, metal A is an electron donor anode. The electrolyte in between is a molten salt. The metal B is an electron acceptor cathode. Metal B is heavier than the electrolyte which is heavier than metal A.

One combination of molten metals, such as magnesium on top (the anode A) and antimony on the bottom (the cathode B) and a salt mixture containing magnesium chloride (the electrolyte in between), are all different densities so that they do not mix (immiscible) but simply rest on top of one another.

The secret is the electrolyte can dissolve

both metal A and metal B. During the charge process, the current separates both

metals out of the electrolyte causing them to gravitate to the two electrodes

leaving behind a thinner electrolyte. When the charge period is complete, there

remains a voltage differential between the two electrodes which can then drive

a current through an external load generating electricity. During discharge the

two metals then recombine in the electrolyte enlarging the electrolyte with

respect to the two electrodes.

The secret is the electrolyte can dissolve

both metal A and metal B. During the charge process, the current separates both

metals out of the electrolyte causing them to gravitate to the two electrodes

leaving behind a thinner electrolyte. When the charge period is complete, there

remains a voltage differential between the two electrodes which can then drive

a current through an external load generating electricity. During discharge the

two metals then recombine in the electrolyte enlarging the electrolyte with

respect to the two electrodes.

The "feasibility battery" was only about 2 inches in height and 3/4 of an inch in diameter. The team is continuing to work on optimizing the system, including the containers used to hold the molten materials, the ways of insulating and heating them, and ways of reducing the operating temperature to cut energy costs.

In the laboratory set up at the right, the liquid metal battery is inside the heavily insulated metal cylinder in the center and was kept at 700°C using external heat sources. In the commercial version, the heat from the chemical reaction should be self-sufficient to keep the temperature steady at 700°C so no external heating source will be necessary.

The wires on top are for charging the battery and for attaching an external load. This was the set up that proved feasibility. The materials that are used in this technology are very low cost. The cost of the final product is expected to be less than $100 per kilo-watt hour (about the same cost as pumping water up a hill to be released later to spin a turbine - the cheapest conventional approach for large scale energy storage). The long-range cost goal is to be about $50 per kilo-watt hour.

The big advantage of liquid metal batteries

is that the current can be 10 times that of regular batteries making it fit for

grid applications. In addition, liquid batteries are expected to have a long

life, in contrast to today's batteries.

The big advantage of liquid metal batteries

is that the current can be 10 times that of regular batteries making it fit for

grid applications. In addition, liquid batteries are expected to have a long

life, in contrast to today's batteries.

As an endorsement of the importance of this research, the MIT project received a grant of about $7 million from the US Department of Energy and $4 million from the French oil company Total. The $11 million-dollar research project was a statement about the potential for this technology.

A company, Ambri Inc., was formed by Professor Donald Sadoway and Dr. David Bradwell to develop an electricity storage solution that will change the way electric grids are operated worldwide. Ambri will enable the widespread use of renewables wind and solar, reduce power prices and increase system reliability.

Ambri, the big-battery startup, has raised more than $50 million in venture capital from investors KLP Enterprises, the family office of Karen Pritzker and Michael Vlock, Building Insurance Bern, Khosla Ventures, Bill Gates and French energy giant Total.

Ambri has been busy designing high-temperature seals and developing its battery management system and heater controls. Ambri has been testing a "fully functioning in-lab" energy storage system, which provides 20 kilowatt-hours of energy storage with a peak capacity of 6 kilowatts. See the Ambri prototype to the right above. A spokesperson for the company said, "We will be building a commercial Ambri system in our lab next year which will be more than 500 kilowatt-hours in capacity. We will deploy our first systems of this size with customers in 2018."

Post a Comment:

You may also like: